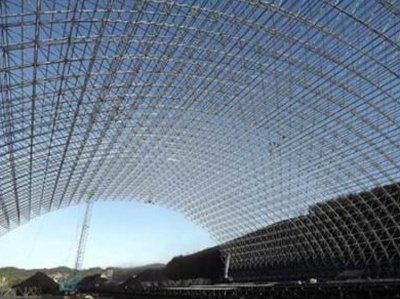

Structural Steel Fabrication

Structural steel fabrication is the process of bending, cutting and modeling steel to create a structure. For structural steel fabrication, steel parts are often put together to create different structures of predefined sizes and shapes. It is a complex process that requires specialized knowledge, skills, and resources to complete successfully. You can refer to Elohim Infra address for quality and fast solutions throughout this process.

Advantages of Structural Steel Fabrication

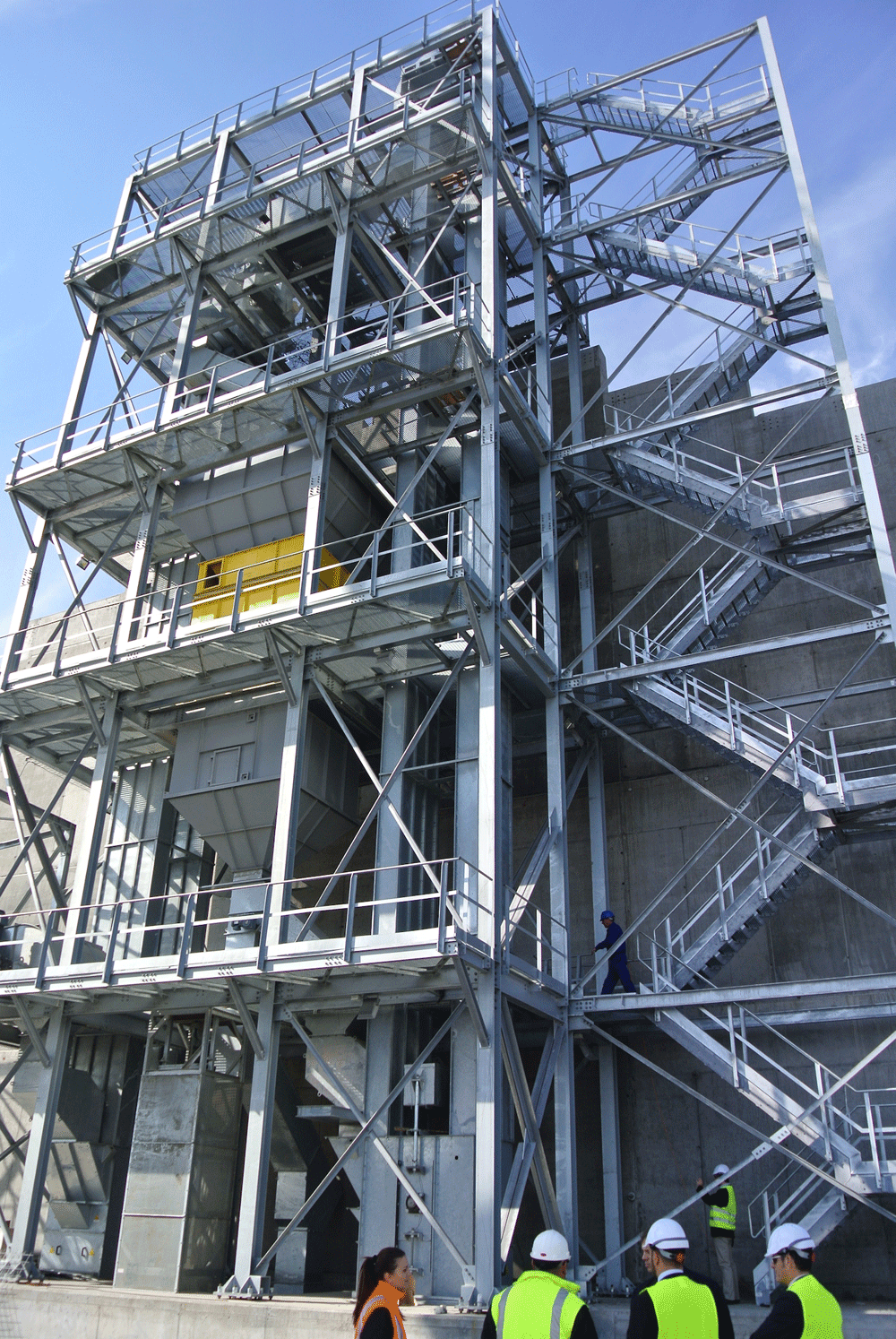

- Steel is extremely durable, resistant to corrosion and must be stretched. The strength of steel is higher than its density, which makes it an excellent choice for construction and manufacturing.

- Structural steel usually comes to the pre-production stage and is manufactured on site. Prefabrications, the amount of work that needs to be done on the site, benefit the acceleration of projects.

- Structural steel is cost-effective compared to other metals such as copper, silver, gold, aluminum and magnesium. This cheapness is very beneficial in construction and manufacturing.

- Structural steel components are easily assembled after fabrication, which, thanks to increased efficiency during assembly, saves significant costs and time.

- The metallurgical properties of steel allow it to be easily produced in any shape and size. Structural steel is produced by welding or bolting together.

- In the steel structure there is a layer of flame retardant material, which makes it extremely resistant to fire. It is water resistant.

- Structural steel is an easily recyclable and environmentally friendly choice for metal manufacturers. As Elohim Infra, we are proudly working for an environmentally friendly and green future.

Integrated Engineering Solutions Provider with Global Footprints

Concept to Commissioning of Infrastructure

11.jpeg)