Light Gauge Framing System (LGFS)

Light Gauge Framing System (LGFS) or Light gauge Steel framing (LGSF) is a construction technology using cold-formed steel as the construction material. It can be used for roof systems, floor systems, wall systems, roof panels, decks, or the entire buildings.

Light gauge steel construction is very similar to wood framed construction in principle - the wooden framing members are replaced with thin steel sections. The steel sections used here are called cold formed sections, meaning that the sections are formed, or given shape at room temperature. This is in contrast to thicker hot rolled sections, that are shaped while the steel is molten hot. Cold formed steel is shaped by guiding thin sheets of steel through a series of rollers, each roller changing the shape very slightly, with the net result of converting a flat sheet of steel into a C or S-shaped section.

The steel used here is coated with zinc (called galvanized) or a mixture of zinc and aluminum (called zincalume or galvalume by some) to protect it from corrosion. The thickness of this coating can be varied to suit a range of environments. Typically, marine environments require the most protection, and dry, arid regions the least.

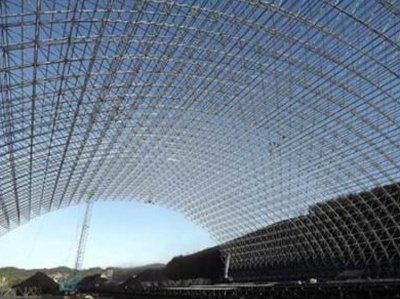

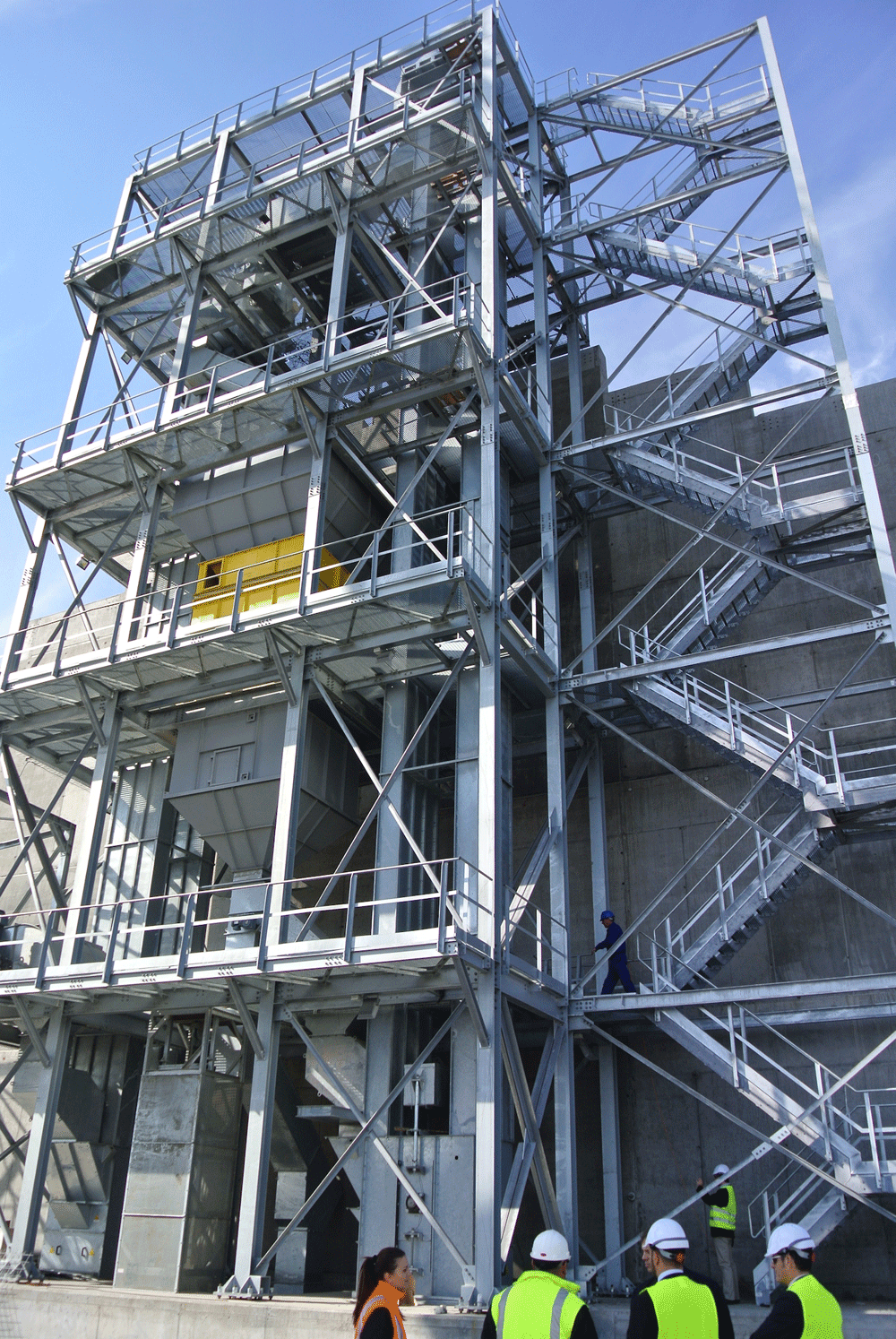

Structures in which the members are made of steel and are joined by welding, riveting, or bolting.

Structures in which the members are made of steel and are joined by welding, riveting, or bolting. Because of the high strength of steel these structures are reliable and require fewer raw materials than other types of structures.

Because of the high strength of steel these structures are reliable and require fewer raw materials than other types of structures. Steel structures, distinguished by the diversity of their shapes and by their architectural expressiveness.

Steel structures, distinguished by the diversity of their shapes and by their architectural expressiveness. Fabrication and installation of steel structures are realized through industrial methods.

Fabrication and installation of steel structures are realized through industrial methods. The main disadvantage of steel structures is susceptibility to corrosion, that requires proper protective measures, such as the application of special coatings and paints, be taken periodically, thereby increasing the service costs.

The main disadvantage of steel structures is susceptibility to corrosion, that requires proper protective measures, such as the application of special coatings and paints, be taken periodically, thereby increasing the service costs.

Light gauge steel structures have many of the advantages of light wood framed structures:

They are light, and allow quick building without heavy tools or equipment. Every component can easily be carried by hand - a house is like a carpentry job on a larger scale. The main tool is a light, handheld screw gun. Since steel is strong, LGS structures are lighter than wood framed structures of equivalent strength.

They are light, and allow quick building without heavy tools or equipment. Every component can easily be carried by hand - a house is like a carpentry job on a larger scale. The main tool is a light, handheld screw gun. Since steel is strong, LGS structures are lighter than wood framed structures of equivalent strength.  Their higher strength allows greater spacing between members when compared to wood frame construction: about 24" (600mm) for LGS vs. about 16" or 20" (400 or 500mm) for wood. Fewer members translates to quicker construction times.

Their higher strength allows greater spacing between members when compared to wood frame construction: about 24" (600mm) for LGS vs. about 16" or 20" (400 or 500mm) for wood. Fewer members translates to quicker construction times. It is able to shape itself to any form, and can be clad and insulated with a wide range of materials.

It is able to shape itself to any form, and can be clad and insulated with a wide range of materials. It is easy to change or modify this construction at any point in its lifespan.

It is easy to change or modify this construction at any point in its lifespan. There are a great range of systems and products catering to this type of construction.

There are a great range of systems and products catering to this type of construction.

In Addition,

Light gauge steel structures are non-combustible, which is a code requirement for some types of structures. Since steel loses its strength in fire quite easily, it must be protected from fire with fire rated sheeting.

Light gauge steel structures are non-combustible, which is a code requirement for some types of structures. Since steel loses its strength in fire quite easily, it must be protected from fire with fire rated sheeting. Light gauge steel structures do not rot, shrink, warp, or decompose like wood structures, and can be used in areas where there is a probability of termite attack.

Light gauge steel structures do not rot, shrink, warp, or decompose like wood structures, and can be used in areas where there is a probability of termite attack.

Integrated Engineering Solutions Provider with Global Footprints

Concept to Commissioning of Infrastructure

11.jpeg)